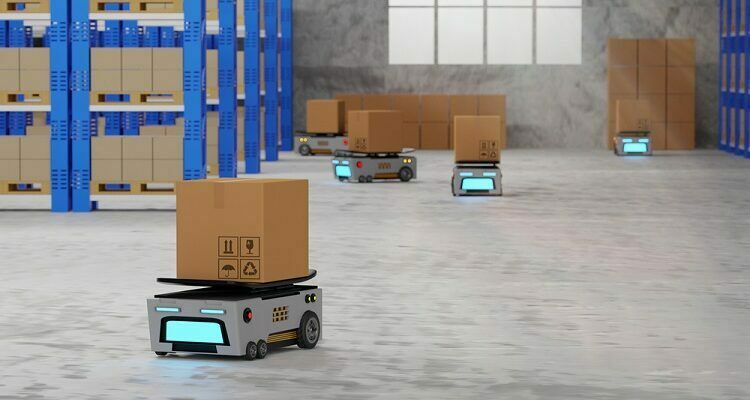

Autonomous mobile robots are reshaping the way factories, production plants, shop floors, and retail spaces function. Learn about their numerous uses and how they are altering organizations worldwide.

AMRs (Autonomous Mobile Robots) have made their way into various industrial settings. Technology advancements have been the driving factor. Improved technologies and computer vision are two essential aspects of optimizing workflow and achieving success. It has also become necessary to use more complex software like AMR in an industrial environment and ensure optimum service capabilities. Read here to know more about Autonomous Mobile Robots.

Table of Contents

Benefits of Using AMRs In a Production Unit

The implementation of Autonomous Mobile Robots can significantly enhance shop floor output. Such robots can easily carry loads from one point to another. Fully functional robots can move loads and find the best possible route on their own in a factory setup.

Carry Loads Efficiently

Autonomous mobile robots, or AMRs, can deliver supplies and parts inside a production plant. You can reduce the physical labor of your factory manpower, such as carrying heavy goods, walking, and transferring stuff from one site to another, by deploying AMRs.

Free Up Manpower from Repetitive Tasks

With the development of autonomous mobile robots, the amount of effort required by the ordinary worker can be significantly reduced. This is advantageous to both the employee and the employer as they can utilize the manpower for other value-added tasks.

Increase Workflow Efficiency

Companies these days are constantly looking for methods to increase their production and efficiency. Typically, this can be accomplished by employing robots to automate operations. Robots have several advantages, including executing repetitive or risky tasks while maintaining consistent quality.

Overall, deploying robots can aid in the reduction of staff health difficulties. The usage of these robots can also free up time for workers to devote to areas of production where robots can’t help.

Conclusion

Traditional versions of robots have already automated many tasks within corporations. Companies must confront the reality that, to remain competitive in the market, they must keep up with mass customization, workforce shortages, and changing needs more than ever before. Businesses need to come up with innovative methods to compensate for these gaps and incorporate robots into their operations.

Comments