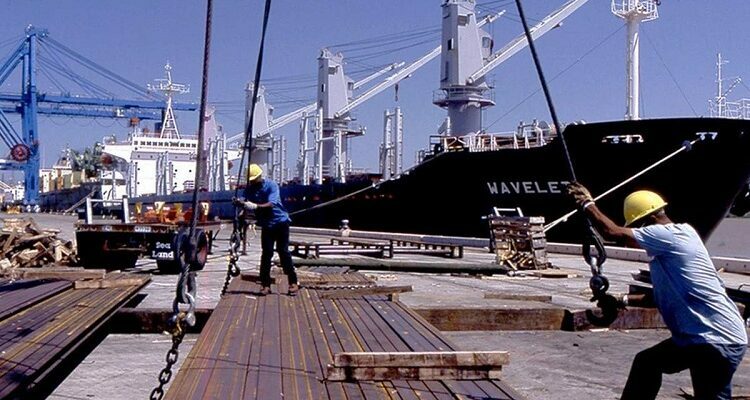

Loading docks are used for loading and unloading cargo from trucks, railcars, or barges. Loading docks allow material handling equipment to move freight around the dock area in a controlled manner. A loading building provides an enclosed space with walls that can open to accommodate many different types of cargoes efficiently, depending on their size and weight. This article will guide how to construct a loading building for rail and barge applications.

The first step in constructing a loading building for rail and barge applications is to identify the facility’s function. The primary considerations are whether it will be used as an open-sided or enclosed structure. How many tracks there will be, what types of equipment need access (trucks or other vehicles), if any overhead cranes exist, and where the trails are concerning other facilities.

The second step is to calculate the area needed for the building. The total loading dock area required can be determined by multiplying the length times width of each track, plus any additional space necessary for driveways and access roads around the facility. A minimum distance of 16 feet must be maintained between tracks so that vehicles have adequate room to maneuver into position.

The third step is to determine the elevation of the tracks. Tracks are generally elevated on columns, but there are other options available, including back-to-back tracks or ground-level trackage where trucks drive on top of barge decking that has been placed over a fill area. If possible, it is best to elevate all railcars and barges to be handled with a crane. If this is not possible, the elevation of the tracks must be determined based on what types and sizes of equipment will need to use them.

The fourth step is to determine the type of materials needed for construction. There are various metal roofing choices that can be used on building with rail and barge applications, including corrugated, perforated expanded metal, pre-engineered standing seam panels, or custom fabricated sheet steel.

The fifth step is to determine the type of flooring needed for loading buildings with rail and barge applications. There are many options available in concrete slabs, asphalt surfaces, or steel decking, depending on what the facility will use and how much traffic it can accommodate. Options such as interlocking pavers where vehicles drive over a series of large stones rather than directly on top of them provide an excellent choice when there is high foot traffic around the dock area and allow easy access for larger trucks that do not need them to turn tight corners at low speeds.

Once these decisions have been made based on information gathered during steps one through four above, development drawings should be prepared by qualified engineers and architects to ensure the proper materials are used. These drawings should include accurate dimensions, elevations, and information about roof types, including support members that need to be placed in concrete footings below them for safety purposes.

Developing a loading building with rail or barge applications is not always easy because it requires attention to detail at every step along the way. It also must consider what types of equipment will use it so that there is no wasted space on either side of the tracks. The five steps outlined above can help simplify things by ensuring everyone involved has access to all essential data before construction begins.

Comments