The world of industrial engineering is constantly pushing its boundaries. New technologies and solutions are constantly emerging to help manufacturers improve efficiency, lower costs, and increase output. One of the most exciting solutions emerging from industrial engineering is semiconductors in industrial automation. The fields of electronics and computing have been intertwined since the beginning of time. Today, the world of industrial automation is no exception.

Table of Contents

1. Integrated Power Management

Integrated power management is one of the most exciting new uses for semiconductors in industrial automation. It’s a concept that allows manufacturers to manage and regulate power consumption across their entire operation more efficiently. As a result, they can reduce energy costs and improve overall efficiency. In addition, the ability to react quickly to changing demand patterns is crucial in today’s manufacturing world. Therefore, manufacturers need to adapt quickly and efficiently, especially when it comes to managing energy consumption.

2. Improved Performance

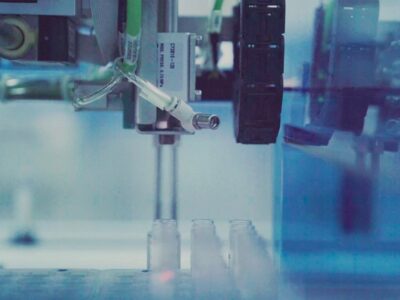

Achieving high levels of productivity and efficiency is a major focus for manufacturers across many industries today. One way that manufacturers can achieve this goal is by using semiconductors embedded into their systems designed specifically with performance in mind. This allows them to make maximum use of their equipment while also improving overall output. Semiconductor-embedded solutions have been used in the automotive industry since the 1980s, but they’re beginning to make their way into other industries.

3. Increased Flexibility

Manufacturers are always looking to improve their efficiency, reduce costs, and increase output. Semiconductors embedded into industrial automation systems allow manufacturers to do all three without sacrificing innovation or efficiency. This is what makes them so important for the future of manufacturing.

The Benefits of Semiconductors in Industrial Automation

There are numerous benefits of using semiconductors in industrial automation. They can reduce energy costs, increase efficiency, and improve overall performance while saving manufacturing companies money in the long term.

Reduce Energy Costs

Manufacturers that use semiconductors in their systems can reduce energy costs by up to 40%. This is a massive amount of savings, especially considering many manufacturers spend anywhere from 10% to 30% of their total energy costs. Furthermore, by embedding semiconductors into their systems and making better use of their equipment, manufacturers will save money on energy expenses for years to come.

Increase Efficiency

Semiconductor-embedded systems are also extremely efficient. They can achieve an 85% increase in power consumption over the same system without embedded semiconductors. This means that manufacturers get the same high output levels with much less power consumption than they previously had with traditional methods. In addition, this efficiency is achieved without sacrificing innovation or efficiency.

Improved Performance

The final benefit of using semiconductors in industrial automation systems is improved performance. Using semiconductors allows manufacturers to make maximum use of their equipment and improve overall output. This is especially true for companies that are looking to increase production levels, which is something that many manufacturers are doing today. Semiconductor-embedded systems allow manufacturers to maximize the amount of energy they’re able to produce with each unit of time.

Comments